Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

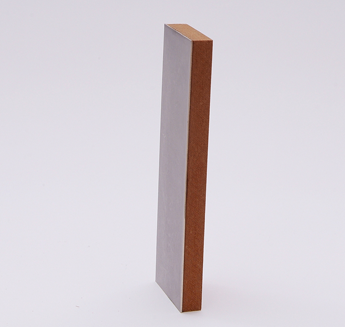

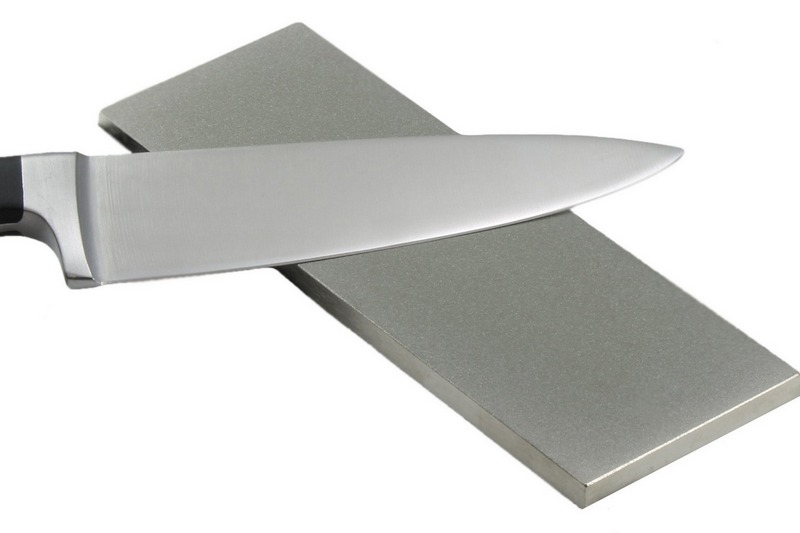

Model No.: DSS

Brand: Hans

Usage: Stone Cutting

Grit: 800-3000

Packaging: Carton Box

Productivity: 10000

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CIF

We want to partner with you to help you achieve your quality, production, and cost objectives.

Product Categories : Electroplated Diamond Products > Special Diamond Tool

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.